M175-240

The HDG M150-240 makes cutting-edge technology available in a lower power range.

-

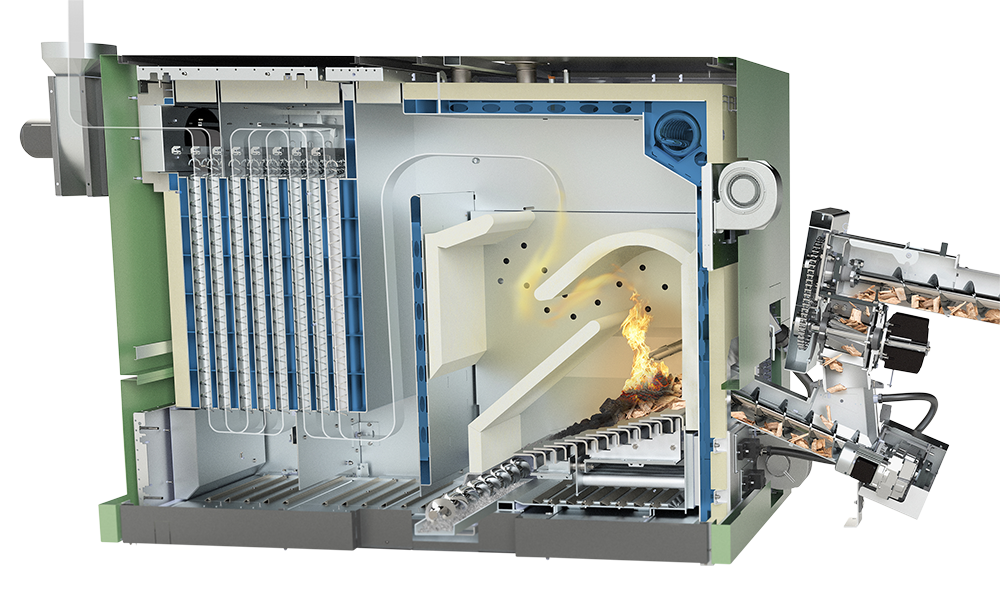

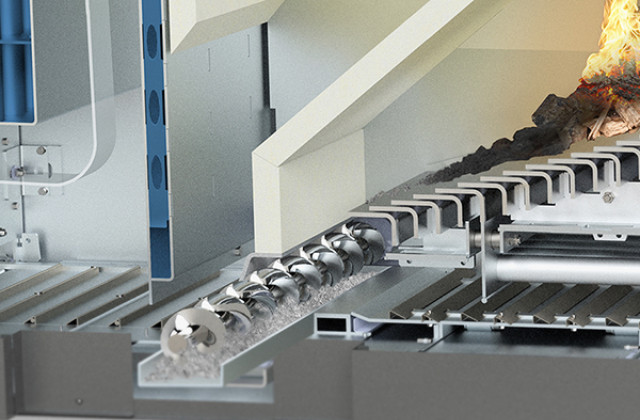

Inside view of the boiler

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1 - 4-chamber rotary feeder with cut connection2 - Stoker screw with dosing container3 - Primary air fan4 - Secondary air fan5 - Automatic ignition with overfill protection6 - 2-zone stepping grate7 - Lower grate ash removal8 - Integrated central ash removal system9 - Secondary and tertiary air supply10 - Safety heat exchanger11 - Heat exchanger with automatic cleaning system12 - Lambda sensor13 - Flue gas fan with negative pressure control14 - Supply and return connections -

Technical data

M150

M175

M200

M240

Nominal thermal power (kW) 150 175 200 240

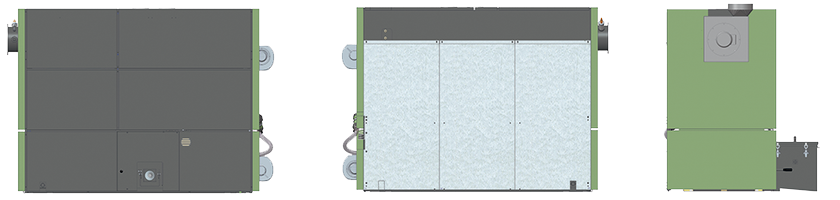

(220 at continuous load)Minimum thermal power (kW) 51,3 52 60 72 Flue gas temperature at nominal thermal power (°C) 160 165 180 195 Flue gas mass flow at nominal thermal power* (kg/s) 0,116 0,116/0,104 0,131/0,118 0,156/0,139 Water capacity (l) 515 515 515 515 Operating pressure (bar) 6 6 6 6 Flue draught requirement (Pa)** 5 5 5 5 Maximum flow temperature (°C) 100 100 100 100 Flue gas pipe connection (mm) 250 250 250 280 Dimensions and weight

M150

M175

M200

M240

Height without attachments (mm) 1832 1832 1832 1832 Width without attachments (mm) 2395 2395 2395 2395 Depth without attachments (mm) 1101 1101 1101 1101 Weight (kg) 2555 2555 2555 2555 * In the case of two specifications, the first refers to wood chip operation, the second to pellet operation.

** In conjunction with flue gas fan and negative pressure control.

High-volume technology in a small format

With the HDG M150-240 wood chip and pellet boiler, HDG is making innovative cutting-edge technology available for the first time in the power range from 150 to 240 kW, setting new standards in efficiency, reliability and convenience. Highlights are the fully integrated fine dust filter, the automatic and complete cleaning including the unique lower grate ash removal as well as the combustion chamber geometry developed together with the Fraunhofer Institute for efficiencies of up to 94 percent!

In short: The HDG M150-240 brings the proven cutting-edge technology of the more powerful HDG M300-400 into the medium power range for the first time.

Combustion chamber temperature sensor

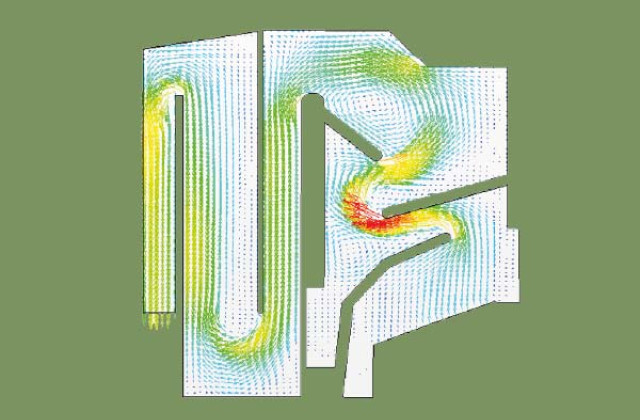

The combustion chamber temperature sensor provides the information for controlling the amount of material, ignition and, above all, the primary air supply. This is needed for pre-drying and outgassing of the fuel and provides the main air for combustion.

Lambda sensor

The lambda sensor measures the residual oxygen following combustion and therefore determines the values for the secondary and tertiary air. Both are admixed with the combustion gases at different times and therefore guarantee extremely clean combustion with the highest levels of efficiency.

Flue gas fan with negative pressure control

The speed-controlled flue gas fan is controlled by a negative pressure control and ensures a constant negative pressure in the combustion chamber. Fluctuating fuel properties and unfavourable flue conditions are therefore effectively compensated.

Maximum efficiency and low emissions

The geometry of the combustion chamber was developed together with the Fraunhofer Institute. The core of this is the integrated centrifugal separator with downstream slowdown and depressurising zone. Due to a 180° deflection, dust is already separated in the combustion chamber. Furthermore, the combustion control takes control right from the start phase and therefore guarantees almost smoke-free combustion.

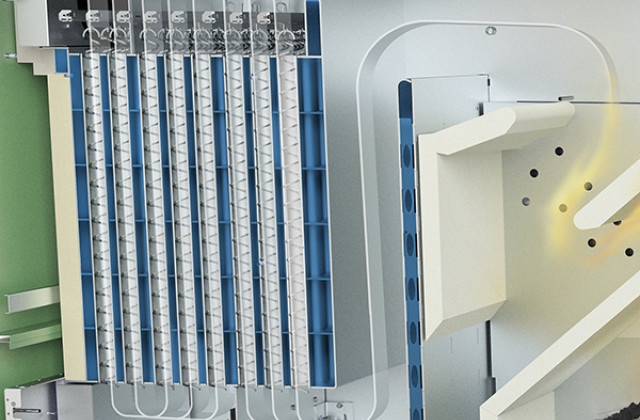

Forced-flow heat exchanger

The layered flow of the heat exchanger optimises the heat transfer and guarantees maximum levels of efficiency. All heat exchanger surfaces are cleaned fully automatically, whereby the maintenance effort is reduced to a minimum.

Extremely clean and quiet

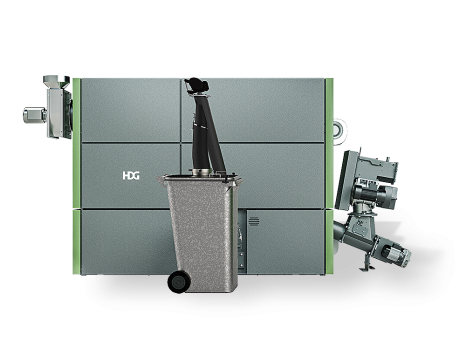

In normal operation, the combustion of the HDG M150-240 runs at low volume and, thanks to the integrated central ash removal system with the new and unique lower grate ash removal system for the removal of the combustion ash as well as the fully automatic cleaning of all heat exchanger surface areas, the heating system virtually cleans itself. In addition, numerous ash removal systems are available for all requirement profiles.

Video of the HDG M150-240 with Vario feeding system

Find out how easy it is to heat with the HDG and experience our flexible wood chip boilers as used by our customers.

Use the entire tree with HDG!

Until now, burning wood chips from branches, treetops and thinning wood has been difficult. Things are different with HDG: Thanks to the integrated fine dust separator, thinning and top wood can now also be used without hesitation.

The advantages:

- Use of high-ash fuels from forest residues

- Electrostatic separator guarantees lowest fine dust values – from heating up to burn-out

- Complete integration in the boiler with low space requirement

- Fully automatic cleaning system of the electrode and separator surfaces

- Integrated filter ash removal of all residues into the ash container

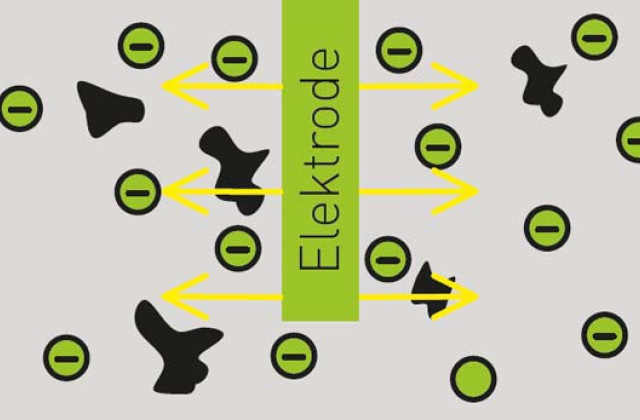

Fine dust particles flow through the exhaust duct with the exhaust air. A high-voltage electrode is used to release electrons

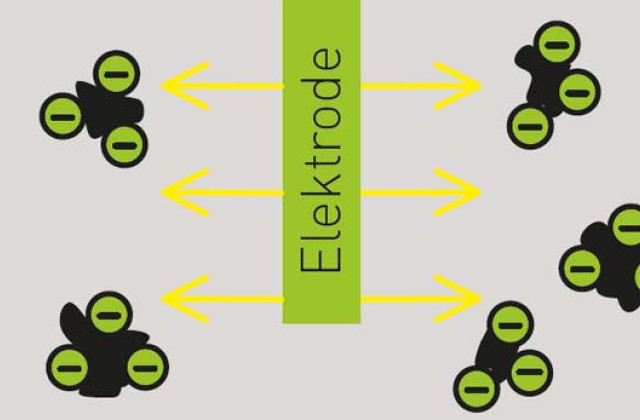

Electrostatic forces move the electrons to the chimney wall. In doing so, the fine-dust particles are charged and also moved to the wall.

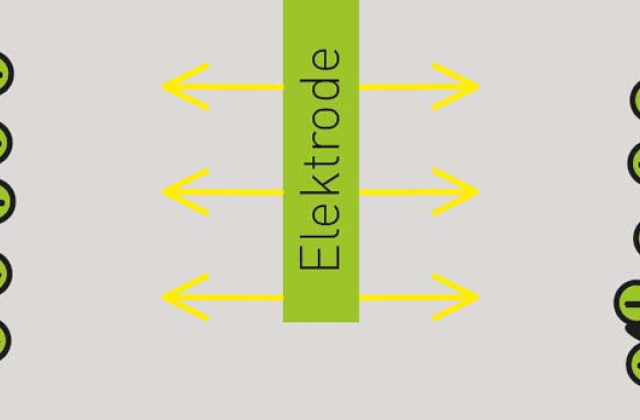

The fine dust collects on the wall and clumps into coarse flakes. These deposits are removed by the automatic cleaning system.