HDG Compact Cascade 130-190(E)

HDG Compact Cascade 130-190(E) offers unrivalled operational reliability and maximum convenience in the smallest of spaces.

-

Hydraulics and installation

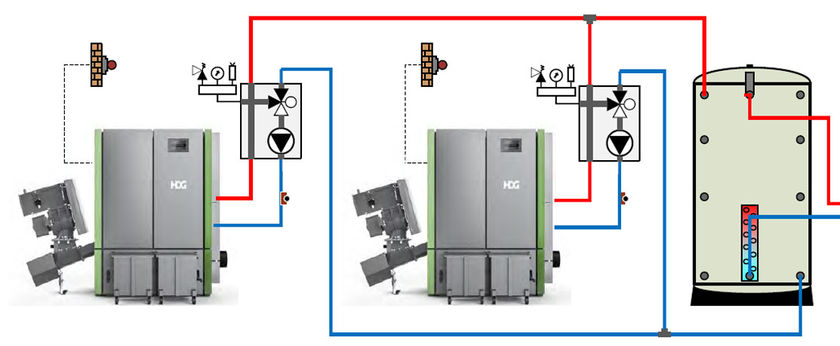

Example installation: A wide variety of solutions are conceivable. For example, the supply from own or joint fuel storage facilities.

Example installation: A wide variety of solutions are conceivable. For example, the supply from own or joint fuel storage facilities. Example hydraulics: Both boilers are connected to a central accumulator. By means of HDG accumulator management, the lead boilers change automatically.

Example hydraulics: Both boilers are connected to a central accumulator. By means of HDG accumulator management, the lead boilers change automatically. -

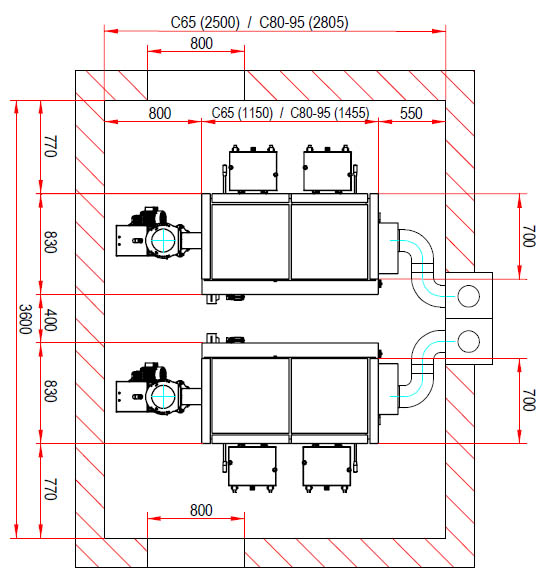

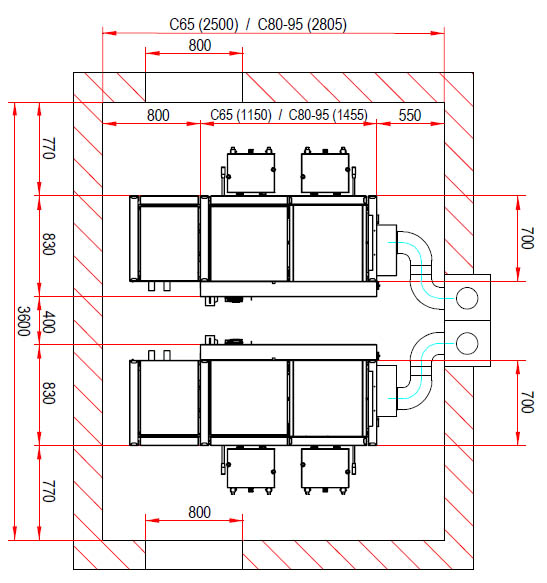

Dimensions and distances

Minimum dimensions: HDG Compact cascade in wood chip operation with delivery system HDG VBZ 120.

Minimum dimensions: HDG Compact cascade in pellet mode with pellet suction system.

Powerful, demand-oriented and safe

For increased power requirements, HDG heating systems can be combined with each other in a cascade configuration. The advantages of a cascade solution are, for example, the high power range, maximum operational reliability and demand-oriented heat supply, especially when energy requirements fluctuate. With HDG, a cascade consists of two boilers that load into a common accumulator.

The HDG Compact cascade thus combines the potential of a boiler from the large power range with the unrivalled flexibility of a multi-boiler system.

Perfectly adapted to the heat demand

A cascade adapts perfectly to the heat demand. When there is a high demand, both boilers run. When demand is low, only one boiler is switched on alternately. Alternating operation reduces the operating hours per boiler and the thermal load decreases. This increases the life expectancy of the installed components.

Clever HDG cascade management

Using the HDG accumulator management system, the installed boilers are alternately assigned the role of lead boiler. Due to the completely autonomous operation of both boilers, the failure of one boiler has no effect on the operation of the second boiler.

Service during operation

The necessary maintenance can take place during operation, as the second boiler continues to run anyway. In addition, the HDG cascade offers maximum safety: If one boiler is not working, the second boiler takes over the basic supply for the connected heating components.

Video of the HDG cascade system

Find out how easy it is to heat with the HDG and experience our flexible cascade solution as used by our customers.

Use the entire tree with HDG!

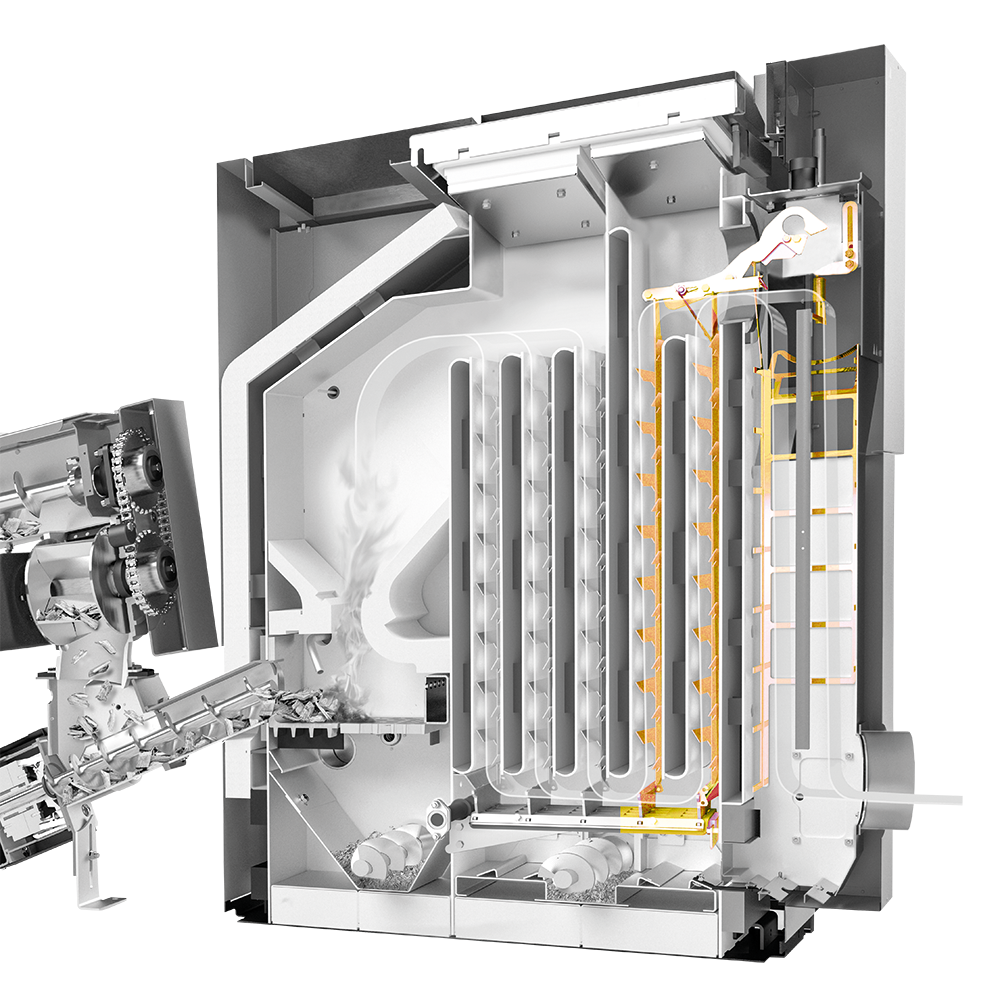

Until now, burning wood chips from branches, treetops and thinning wood has been difficult. Things are different with HDG: Thanks to the Vario delivery system and integrated fine dust separator, coarse and ash-rich fuel can now also be used.

Integrated fine dust filter

With our fine dust separator technology, fuels rich in ash can also be used. Due to the integration in the boiler, only 5 cm more space is required. All fine dust particles are cleaned and collected fully automatically and conveyed to the central ash container just like the other combustion residues.

The advantages:

- Use of high-ash fuels from forest residues

- Electrostatic separator guarantees lowest fine dust values – from heating up

- until burn-out

- Thanks to complete integration in the boiler only about 5 cm

- additional space required

- Fully automatic cleaning system of the electrode and separator surfaces

- Integrated filter ash removal of all residues into the ash container

- Low flue gas pipe connection – ideal for existing fireplaces